Kicking Off Batch 4 of the Hardtech Innovation Accelerator

Batch 4 Kick-Off Week: A Recap

It’s that time of the year again: our flagship program, the Hardtech Innovation Accelerator, is back for its fourth round, bringing six new startups focused on building ambitious solutions for a net-zero future. Read on to learn more about the teams and their first week at MotionLab.Berlin.

It’s that time of the year again: our flagship program, the Hardtech Innovation Accelerator, is back for its fourth round, bringing six new startups focused on building ambitious solutions for a net-zero future. Read on to learn more about the teams and their first week at MotionLab.Berlin.

For the fourth year in a row, every November, MotionLab.Berlin opens its door to the latest batch of Hardtech Innovation Accelerator startups. As is tradition, these newly-selected teams dive right into their seven-month journey with a kick-off week. The program begins with foundational workshops and sessions designed to tackle the biggest challenges that early-stage hardware startups face from day one.

Laying The Solid Foundation

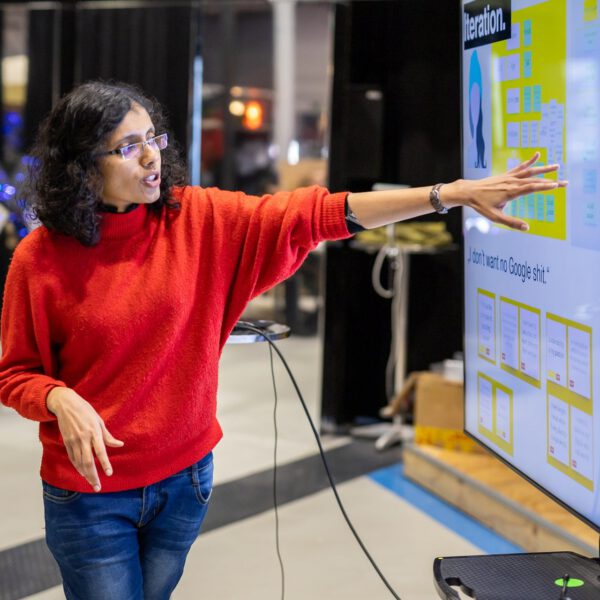

“If you look at the kick-off week plan, it might seem pretty packed—and for good reason. We want our startups to build a solid foundation right from the start, so they can seamlessly navigate phase one of the program, which focuses on topics like market validation and problem-solution fit,” says Marianna Egressy, Head of Accelerator & Ecosystem at MotionLab.Berlin and the mastermind behind the Hardtech Innovation Accelerator.

According to Marianna, market validation must come first before any building begins. This approach ensures that a product idea is viable and helps identify the customers who would ultimately buy it. Even the famous “Prototyping on a Budget” workshop, where teams create their first prototypes using simple materials like cardboard and tape, is designed not only to demonstrate how a product might look but also to show how customers could interact with it.

“I often see people come in thinking that we’re going to head to the labs on their second day and start building something. The team might end up developing the most sophisticated robot, but first, they need to determine if there is an actual need for it, if there is a market for it, and if someone out there wants to buy it. Otherwise, all their efforts will go in vain before they even realize it,” Marianna concludes.

More Than Just Saving the Oceans

Batch 4 of the Hardtech Innovation Accelerator is exceptionally diverse, with projects ranging from carbon capture solutions to IoT devices, addressing challenges in sectors like wildfire protection and bike safety. This raises a broader question about what truly defines climate tech and how the teams’ solutions can play a role in it.

“Climate tech isn’t just about cleaning the air and oceans; it’s also about transforming existing industries and social structures into more sustainable ones. In that sense, all of the projects in Batch 4 contribute to that goal. That was my key takeaway when we were selecting these startups,” says Marianna when asked about the new batch of the accelerator.

Introducing the Teams of Batch 4

As diverse as they are, these teams are united by a common goal: making the future more sustainable. Meet the innovators behind Batch 4 of the Hardtech Innovation Accelerator.

CIYANO

Did you know that bioplastics could reduce carbon dioxide emissions by at least 30% and lower carbon footprints by an impressive 42%? Servet, Hermine, and Alessandro from CIYANO are working to make this a reality. Together, they aim to tackle plastic waste by offering 100% biodegradable packaging solutions made from cyanobacteria, providing a sustainable alternative to conventional plastics and helping combat pollution.

yamakoe

The yamakoe team, consisting of Lara, Phil, and Jesus, is dedicated to protecting lives, preserving habitats, and combating climate change through innovative wildfire detection. This is how they describe their work: “Imagine a super-smart smoke detector you might have in your house, but this one is designed specifically for forests. It’s built to detect even the slightest hint of smoke, so it can spot a fire while it’s still small. Each sensor we place on the trees isn’t working alone—it’s part of a vast network, spread out across the forest, almost like guards keeping watch over every part of the land”.

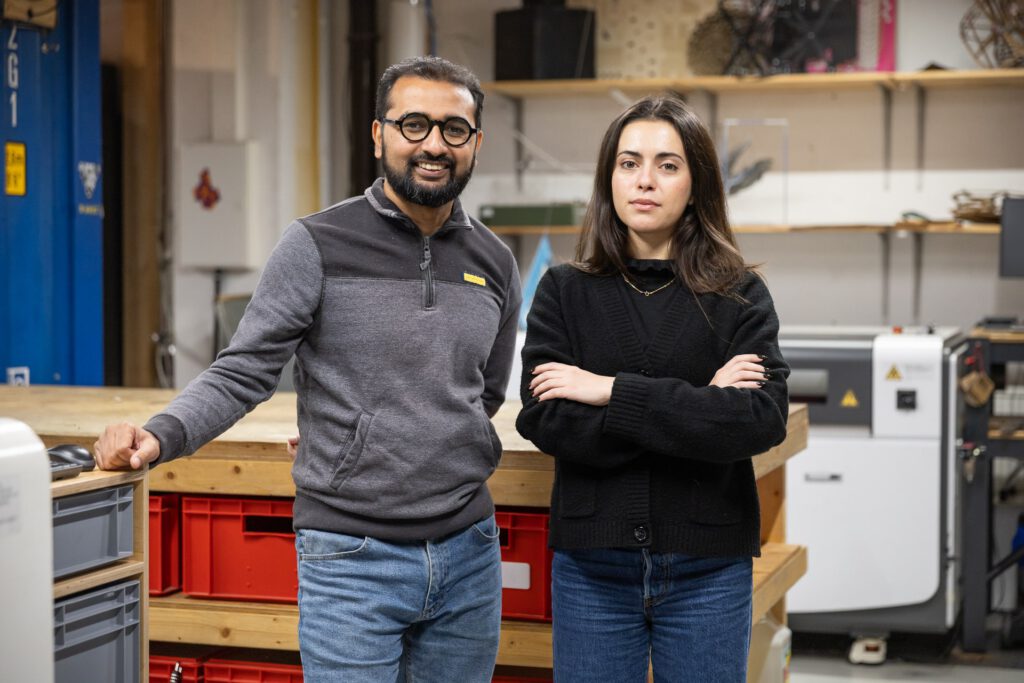

MGC Factory

Karina and Andrew are leading MGC Factory with the goal of making hardtech innovation more accessible. MGC Factory brings the tools, expertise, and efficiency of the world’s most advanced manufacturing facilities to cities across Europe. By creating micro-factories for locally-produced IoT devices, they are reshaping the electronics design and manufacturing ecosystem. Their pilot platform is currently unfolding in Berlin.

Flux Cap Energy Tech

Flux Cap Energy Tech, led by Lina, Patrick, and Florian, is developing a core technology to enhance energy efficiency in various applications, including coin mining and server farms. With a focus on bringing their innovation to market, they aim to create both ecological and economic benefits. Their product captures low-grade heat—generated from relatively small temperature differences—and converts part of it into power while redirecting the remaining heat for reuse.

Climalyst UG (Haftungsbeschränkt)

ENGEL

ENGEL, led by César, Teresa, Marvin, and Aleksandra, is a team of passionate cyclists with expertise in hardware, software, business, and marketing. Motivated by their own experiences with bike accidents and theft, they’re dedicated to enhancing cycling safety. Their IoT tail light device detects accidents, notifies emergency contacts with GPS location, and serves as an anti-theft device and parking alarm. With additional features like predictive maintenance and performance analytics, ENGEL aims to make cycling a safer and more attractive alternative to car travel, reducing city traffic and CO₂ emissions.

Follow Batch 4 On Their Journey

And just like that, the kick-off week wrapped up with Pitch and Pizza, where the teams had the chance to pitch their startups to lead mentors Daniel Flynn and Fernando Germán Torales Chorne, CEO and CTO of Bearcover. Starting this week, the teams will meet regularly with their mentors to validate product ideas and define target customers.

Stay tuned for more insights from the journey of Batch 4, and if you have a game-changing climate tech idea, subscribe to our newsletter to learn how you can join the next batch.

OUR HARDTECH INNOVATION PROGRAM

IS SUPPORTED BY