In 3 simple steps to a working prototype using 3D printing

Last update: 04.2023

THE BASICS

What is 3D printing?

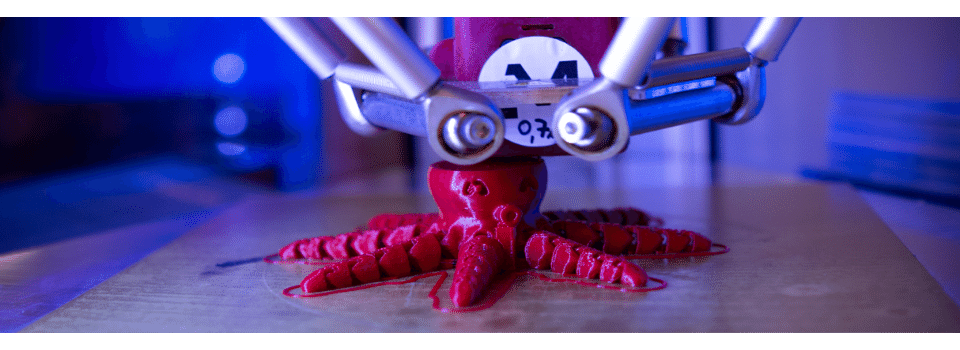

As opposed to subtractive manufacturing, 3D printing or additive manufacturing regroups a number of techniques relying on the process of creating an object by aggregating material layer by layer. Dating back to the 1980s, 3D printing has since evolved in numerous ways. Many new techniques and materials have been developed and used in these processes allowing it to broaden the span of its applications.

Initially developed as a rapid prototyping technology, additive manufacturing is now truthfully used to produce finished parts from the aerospace and automotive industries and in numerous other specific fields in the food or pharmaceutical industries.

THE 3D PRINTING GUIDE

In 3 simple steps to a working prototype using 3D printing

Experience shows that people have two opinions about 3D printing. Either they think it is a gimmick or they think that using a 3D printer is very complex and complicated. But neither of these opinions are true.

In recent years, innovative companies such as Mark3D GmbH, Formlabs and WASP have taken up the cause of industrializing 3D printing. Get rid of the belief that 3D printing is just a gimmick and see for yourself what high-quality projects can be realized today.

Coming back to the belief, 3D printing is too complex – trust me, if you once understand the principle of a 3D printer, it is actually a quick and easy way to start creating a prototype. In the following step for step guide, you can learn how.

Please have in mind: Building a prototype is a necessary step, before you can start production and convince people to buy your product. The importance of a presentable prototype is only too often underestimated. Your prototype does not have to be perfect, but it will give you a better understanding for your product and possible pain points.

FIRST STEP

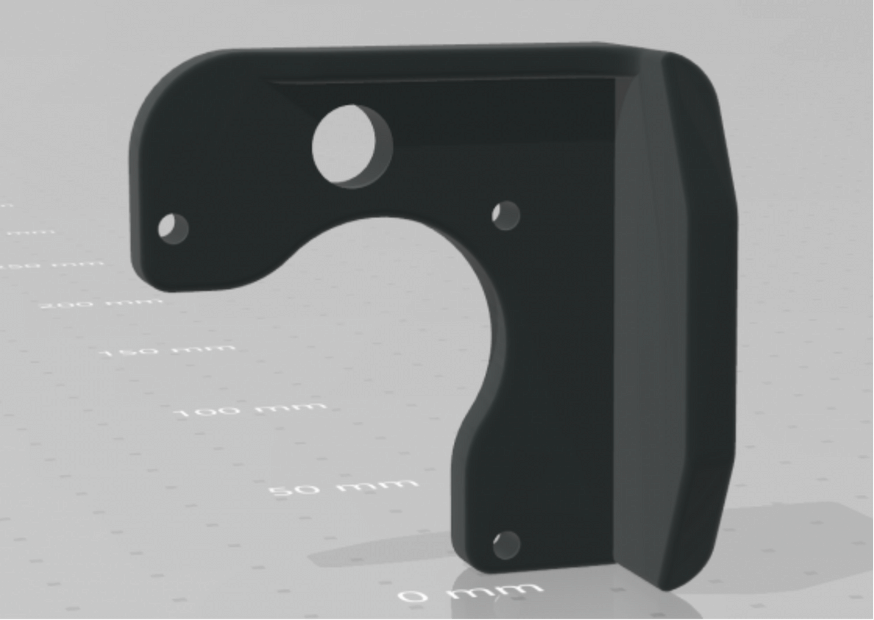

Modelize

It all starts with a digital 3D model either built using a CAD (Computer Assisted Design) software or resulting from a 3D scan. To be printable, the model needs to be generated in printable file format such as .STL or .OBJ .

SECOND STEP

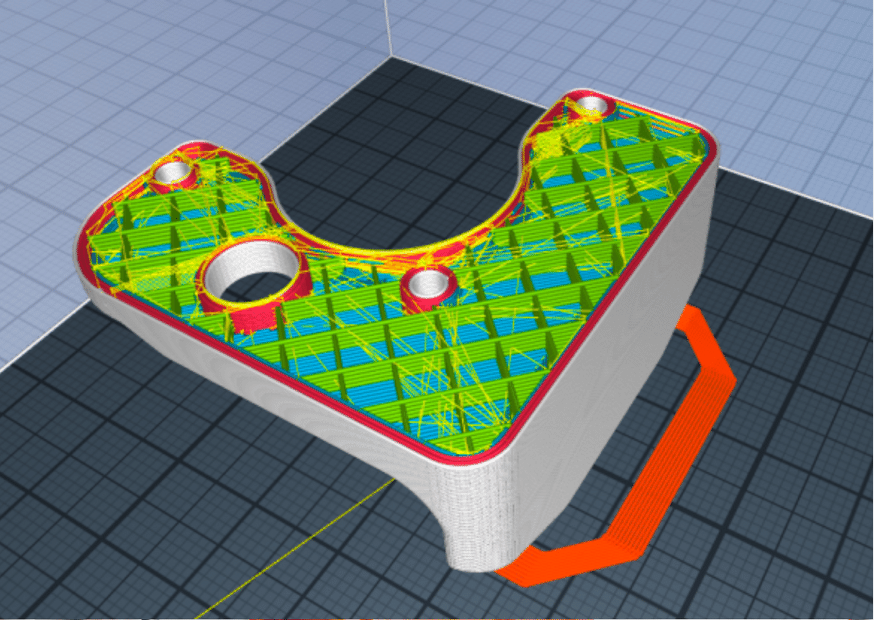

Slize

The model is then sliced into numerous 2D layers by a slicing software, usually dedicated to a specific printer model or manufacturer. During this step, you might also choose to add some supporting structure making up for the design specifications exceeding the printer’s performance. Amongst the usual settings, you’re usually able to tune and refine your layer height (ie.precision), infill type and density (time vs. strength) as well as the width of your bottom, top and wall layers.

THIRD STEP

There are several types of 3D printing technologies, which include:

- Stereolithography (SLA)

- Fused Deposition Modeling (FDM)

- Multi Jet Fusion (MJF)

- Direct Metal Laser Sintering (DMLS)

- Digital Light Process (DLP)

- Selective Laser Sintering (SLS)

- PolyJet

- Electron Beam Melting (EBM)

- Continuous Filament Fabrication (CFF)

Stereolithography

(SLA)

Fused Deposition Modeling (FDM)

Multi Jet Fusion

(MJF)

Direct Metal Laser Sintering (DMLS)

Digital Light Process

(DLP)

Selective Laser

Sintering (SLS)

PolyJet

Electron Beam

Melting (EBM)

Continuous Filament Fabrication (CFF)

They are very different in the way they function to aggregate layers of material together. Some use heat to melt or fuse the material and dispose of it layer after layer through a fine extruder head.

Others rely on the use of light, laser or UV rays to aggregate resin monomers into polymers. Some are very specific in the type of material they are able to print and others and more versatile.There’s rarely a simple answer when selecting a 3D printing process.

That’s why we typically point to five key criteria to determine what technology will meet our needs:

Budget

Mechanical

requirements

Cosmetic

appearance

Material

selection

Geometry

PROTOTYPING & 3D PRINTING

Why should I use a 3D printer for prototyping?

The process of adding material layer by layer makes the design of complex parts easier and strongly contributes to the emergence of generative shape design or organically designed parts based on biomimicry. 3D printing also allows the production of lighter parts than traditional machining and manufacturing processes by only putting material where the model or its supporting structures require it.

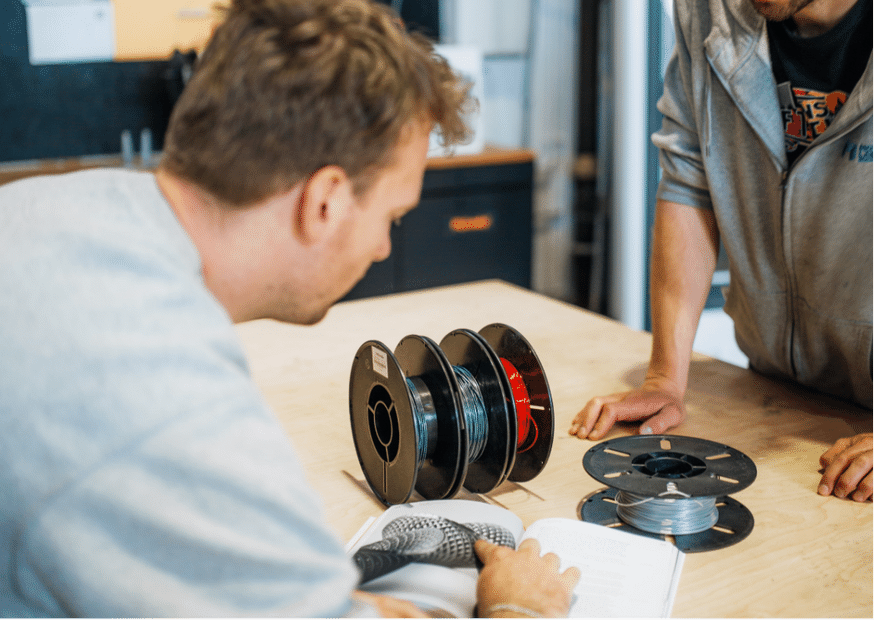

Furthermore, most 3D printers work with a wide range of materials without requiring any significant modifications making this process even more versatile and cost-effective.

A wide variety of filament materials can be extruded, including thermoplastics such as acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), high-impact polystyrene (HIPS), thermoplastic polyurethane (TPU) and aliphatic polyamides (nylon). Using other technologies such as SLA, you have access to a whole range of resin based materials with various properties and applications. Continuous Filament Fabrication (CFF) even allows fibers and composites to be printed in combination with a nylon matrix.

It is both a gain of time and resources not to require special machinery or new processes when it comes to prototyping or manufacturing.

MOTIONLAB.BERLIN

3D Printing Area

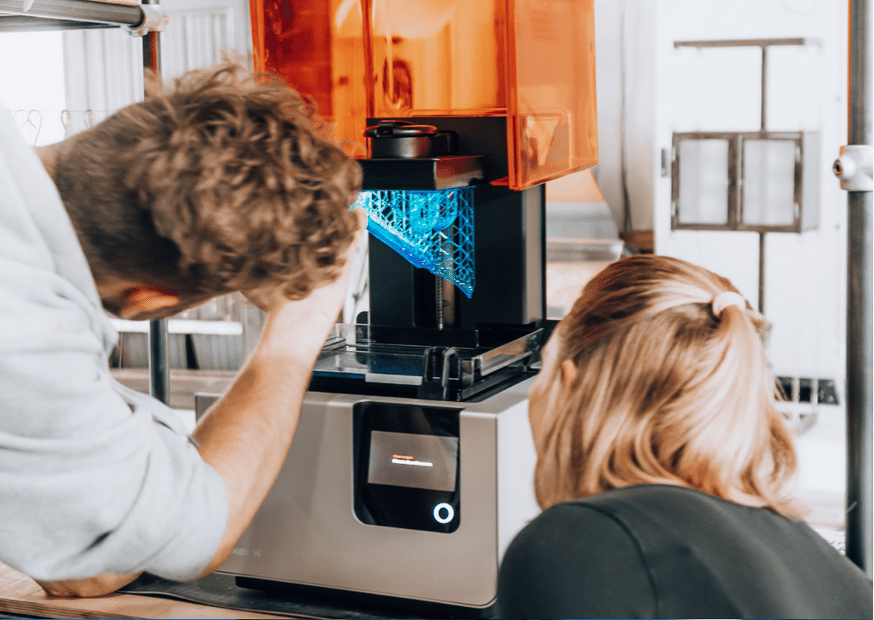

MotionLab.Berlin is a Hardtech Innovation Hub & Makerspace with a large community of startups, entrepreneurs, technical experts and trainers. Our 3D-printing lab is used daily by many of our members and plays a big part in their prototyping process.

Many of which learned how to use the printers during the following workshops:

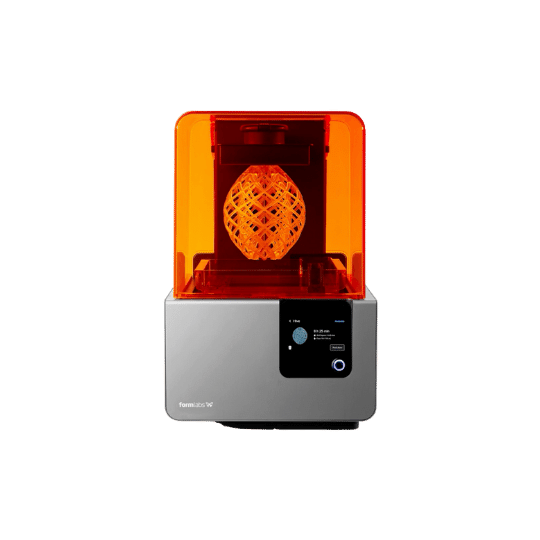

- Introduction into 3d printing with SLA technology [on the Formlabs 3d printers]

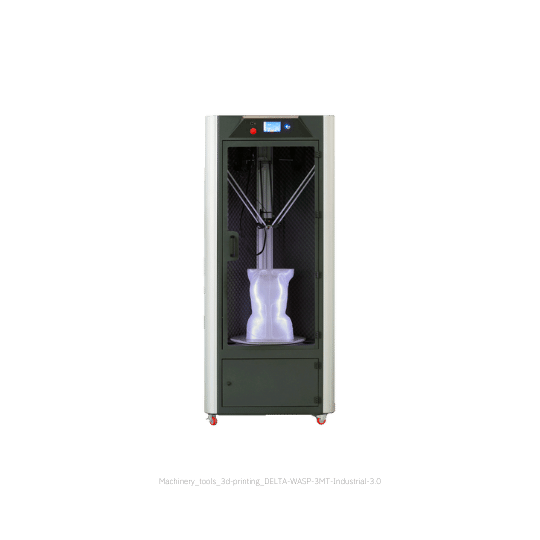

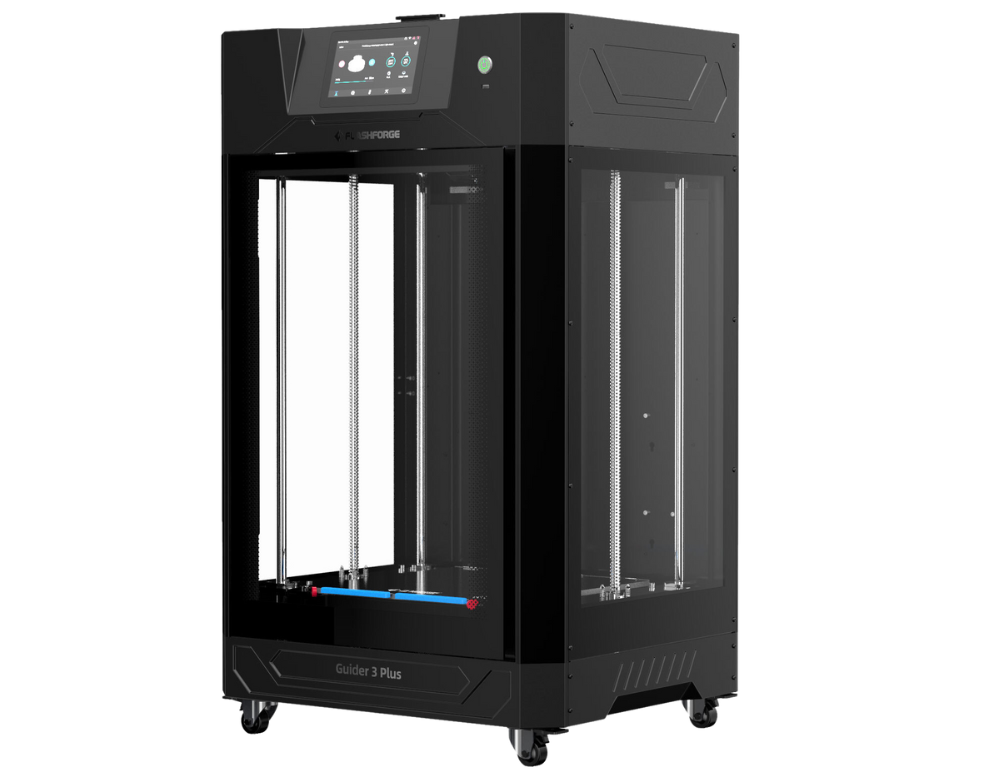

- Introduction into 3d printing with FDM technology [3d printers: CraftBot, DELTA WASP etc.]

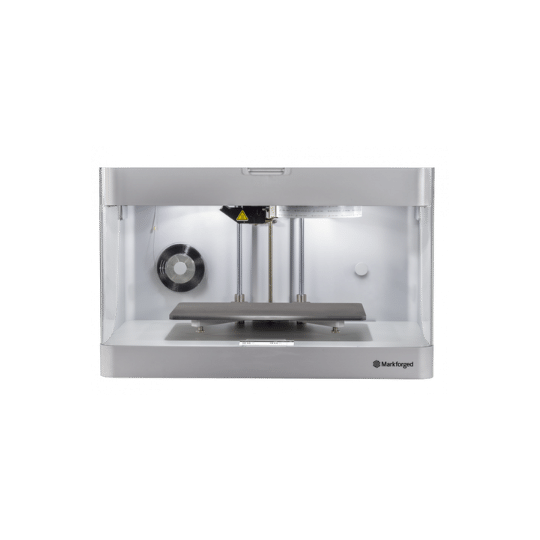

- Markforged Introduction [CFF]

Your first prototype is only a few hours of training (and printing time) away!

If you have been waiting for sign – this is it 😉

Don’t you have a project that has been on your mind for a long time, but you have hesitated to realize it?

Let me tell you: in the end it will be easier than you might think now. The hardest part is always the start. And to make that as easy as possible, we at MotionLab.Berlin decided agains machine costs per hour. That’s why we included a machine flatrate in our Professional Membership. That means, you do not have think of costs, if you iterate at a certain point. Just do it again and you will learn a lot from the mistakes you made before.

WHICH PRINTER DO WE HAVE?

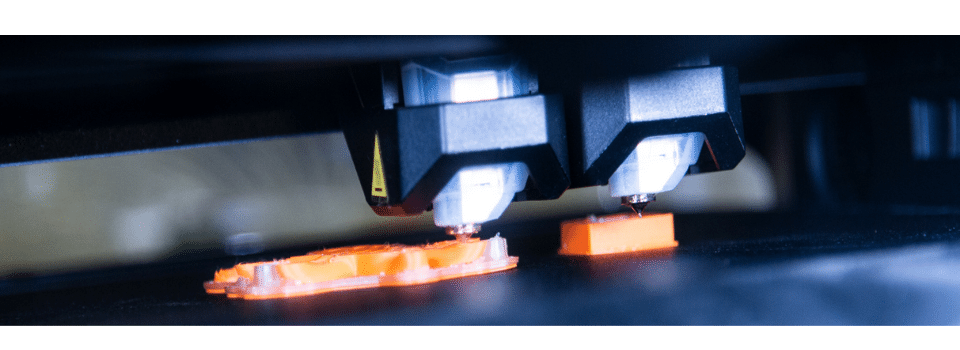

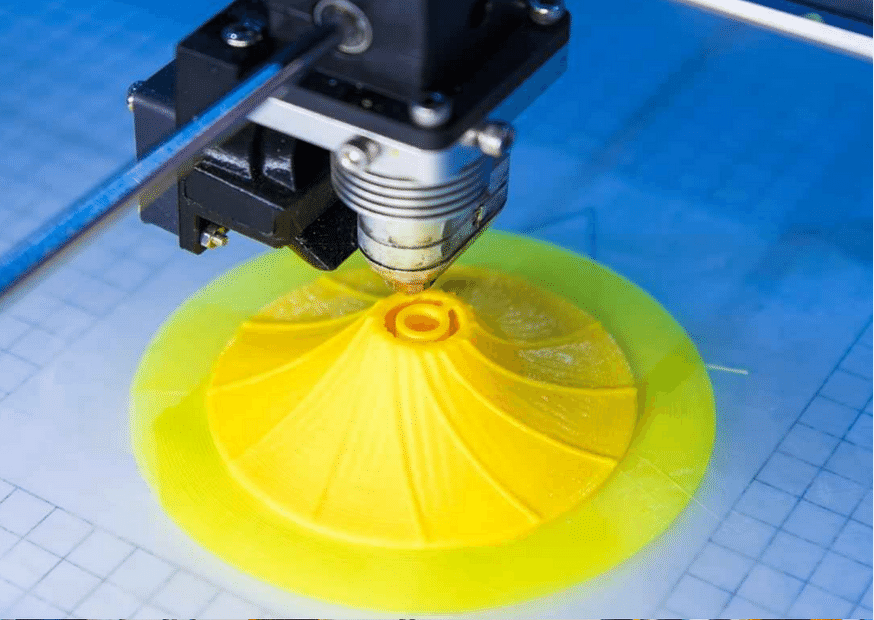

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a 3D printing process that uses a continuous filament of a thermoplastic material and deposes it in a layer-by-layer fashion

Continuous Filament Fabrication (CFF)

Continuous Filament Fabrication (CFF) is a 3D-printing process binding fibers with matrix materials (here: Onyx) to help them take shape, yielding incredibly lightweight, robust structures.

Stereolithography (SLA)

Stereolithography (SLA) & Low Force Stereolithography (LFS)™ is a3D-Printing technology using photochemical (here UV) processes by which light causes chemical monomers and oligomers to cross-link together to form polymers. Form 2 and Form 3

You have questions regarding the 3D printing area or the whole workspace? Please use the contact form and reach out to our prototyping team or book a tour and come by!